- Air Homepage

- Alberta Air Quality

- Continuous Emission Monitoring Systems

- Continuous Emission Monitoring Equipment

The CEMS Code: Alberta's Guide to Continuous Emission Monitoring Equipment

This article outlines the essential protocols and meticulous testing procedures. In this section, you will learn how to maintain accurate and reliable continuous emission monitoring equipment and find valuable insights for certification, recertification, and component replacement.

The purpose of this guide is to explain how Continuous Emission Monitoring Systems (CEMS) are certified and recertified. From the Operational Test Period to meeting performance specifications, the article describes how to ensure emission data is accurate and reliable. We start with an overview.

What is a Continuous Emissions Monitoring System? CEMS measure air emissions from industrial processes on a continuous basis. Monitoring pollutants like carbon dioxide (CO2), sulfur dioxide (SO2), and nitrogen oxides (NOx) helps industries comply with environmental regulations.

Why are they important? CEMS protects the environment by monitoring and helping us control emissions. Keeping track of emissions helps industrial personnel identify and fix problems quickly, ensuring they stay within the law. Here are some process details:

- Analyzers measure the concentration of specific gases.

- Get samples of the emissions from the stack or duct using sample probes.

- Data Acquisition Systems (DAS): Record and store gas analyzer data.

- Ensure the gas analyzers are accurate by calibration, comparing their readings to known standards.

What is temporary CEMS equipment? For short-term monitoring, such as during maintenance or testing, temporary CEMS equipment is used. It's flexible and can be set up and taken down quickly.

No continuous emission monitoring equipment needed here

No continuous emission monitoring equipment needed hereWhat does RATA stand for? It stands for Relative Accuracy Test Audit. CEMS readings are compared to a reference method to make sure they're accurate. It helps verify that the system works.

Calibration drift is when a gas analyzer's accuracy slowly changes over time. Calibration checks are necessary to keep the readings accurate. The analyzer needs to be calibrated if the readings drift too far from the standard.

What are some examples of how CEMS is used? Imagine a coal-fired power plant. Smokestack emissions are monitored by a CEMS. CEMS continuously measures CO2, SO2, and NOx emissions. The plant operators can then reduce emissions with this knowledge by adjusting the combustion process or using pollution control equipment if the levels get too high.

What does the Alberta CEMS Code do? It provides guidelines for installing, operating, maintaining, and certifying CEMS. This makes monitoring reliable and consistent because all industries follow the same standards.

After major component replacements, the person responsible for recertifying must undergo rigorous testing within a certain period of time. As well as minor component replacements, the guide emphasizes quality control checks and recommends regular testing. This resource, taken from Section 5 of the Alberta CEMS Code, is ideal if you want to make sure their continuous emission monitoring systems are accurate.

Section 5.1 - Certification, Recertification, and Component Replacement

Certification means proving that the Continuous Emission Monitoring System (CEMS) works as it should.

After installing new continuous emission monitoring equipment, it's a good idea to run it for about a week while the pollution source (like those in a factory) is running. This helps make sure everything is working right before official testing begins.

Certification Requirements:

- You need to test and certify a new CEMS installation or a CEMS that's completely replaced.

- If you only replace some parts, you might not need full certification, just recertification for those parts.

- To get certification, systems have to meet certain performance standards within a specific time frame (either 120 unit operating days or 180 consecutive calendar days, whichever comes first) from when the emissions first go into the air.

- The CEMS needs to be fully operational for at least 168 hours during an Operational Test Period, while the pollution source is running.

Getting certifications and testing done

Getting certifications and testing doneOperational Test Period:

- During the Operational Test Period, operators need to run the CEMS normally and follow certain procedures.

- They mustn't do any unplanned maintenance or repairs during this time, except for scheduled checks and tests.

- Calibration and tests might pause for a bit, but only for specific checks, and they have to record when this happens.

- If something doesn't work right during this time, they need to investigate and fix it before continuing.

Additional Tests for Certification:

- The technicians also need tests during the Operational Test Period, including checking how well the CEMS measures gas concentrations, temperature, and flow rates.

- They need to do a calibration drift test, which checks if the measurements stay accurate over time.

- They have to test the system's accuracy and bias.

- If they use a correction factor to make measurements accurate, they have to set it up before certification and use it during testing.

- If the Operational Test Period gets interrupted (like if the factory shuts down), you need to record when it stopped and start it again when the factory restarts.

- If anything goes wrong during the Operational Test Period, figure out why and fix it.

Repeating Tests:

- If a certification test, especially the Relative Accuracy Test Audit (RATA), fails during or after the Operational Test Period, you might have to restart the Operational Test Period and do the test again.

- The results of these tests also count towards meeting future testing requirements.

Director Sign-off and Reporting:

- Once everything is working correctly and meets all the requirements, the CEMS is certified. There's no need for special permission from the director.

- Operators will have to report their findings and test results as per the reporting requirements.

- In a nutshell, this section is all about making sure the pollution monitoring system works correctly and provides accurate data about emissions from industrial sources. It involves lots of testing and checks to ensure everything is in order.

5.2 - Major Component Replacement and Recertification

This section is about what to do when you replace big parts of your pollution monitoring system (CEMS) and how to make sure it still works correctly. Temporary replacements or rotations of parts are covered in another section.

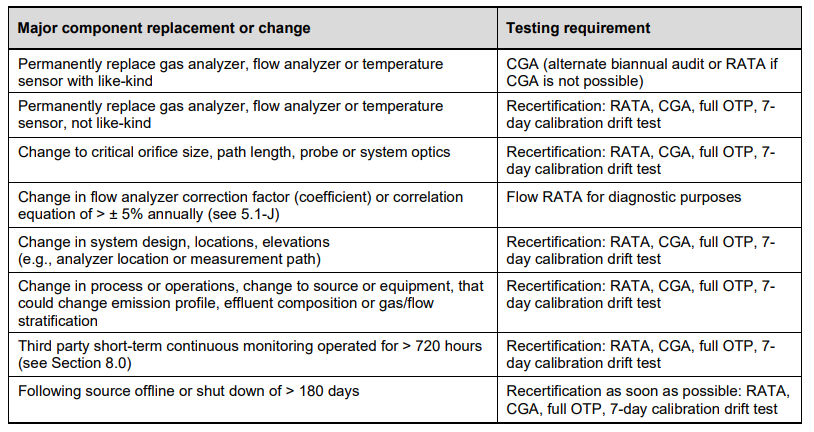

When to Test and Recertify:

- Whenever you permanently replace a major part of the CEMS or make any changes that could mess up how it works or the data it gives, you need to do performance tests.

- These tests have to meet certain requirements listed in the table below, or you follow the manufacturer's testing and quality control instructions in your plan (QAP).

- It's up to the person in charge to decide if a change might mess up the CEMS or the data it gives. This table doesn't list every possible change that could cause problems. If there's a failure in the tests after a change, the person in charge needs to figure out when things went wrong (see Section 7.6 of the code).

Testing and changing continuous emission monitoring equipment

Testing and changing continuous emission monitoring equipmentWhat to Test For:

- The table above has a list of changes and what tests you need to do when you make these changes. For example, if you replace a gas analyzer with a similar one, you need a CGA (Continuous Gas Analyzer) test.

- If you replace a gas analyzer, flow analyzer, or temperature sensor with something different, you need a more comprehensive recertification test, which includes a RATA (Relative Accuracy Test Audit), CGA, full Operational Test Period (OTP), and a 7-day calibration drift test.

- There are other changes listed too, like changing the system's design or the way your factory works. They also need these tests to make sure the CEMS still works correctly.

Changes to analyzers need recertification tests.

Changes to analyzers need recertification tests.Recertification Recommended:

- Even if you replace a part with a similar one and don't need recertification, it's still a good idea to do a RATA test after a change.

- The results of tests done for recertification can also count toward meeting future testing requirements (like RATA frequency).

Timing Matters:

- When you make a change and need recertification, you have a maximum of 90 days to complete all the required tests and meet the performance standards.

- Once you successfully meet these requirements, your CEMS is recertified.

Reporting:

- After recertification, you need to let the director know what changes were made and if your monitoring plan changed.

- This should be done within 30 days after recertification.

- In simple terms, this section is all about making sure your pollution monitoring system stays accurate and reliable, even when you replace or change big parts of it. It involves doing certain tests and reporting the results to make sure everything's working as it should.

5.3 - Regularly Replace, Repair, and Maintain your Continuous Emission Monitoring Equipment.

If you're replacing or repairing small parts of your CEMS, you need to do quality control checks and follow the procedures the manufacturer and your quality assurance plan (QAP) specify. Minor component replacement means you're changing something in the system that shouldn't really mess up how it works or the data it gives.

Quality Control Checks:

- The manufacturer and your QAP will tell you what checks you need to do when replacing or repairing minor components.

- There's a table in Appendix C that gives you some examples of these checks, but it doesn't cover everything. It's up to the person in charge to decide what tests and checks to do and to write them down in the QAP.

Monitoring After Maintenance:

- After you replace or repair something, it's a good idea to keep a close eye on the system to make sure everything's working as it should.

- Even though you don't need to do a full recertification after minor continuous emission monitoring equipment replacement, it's recommended to schedule a regular RATA test shortly after making any changes to the system. This helps ensure your system is still accurate and reliable.

In simple terms, this section is about doing checks and following procedures when you replace, repair, or do maintenance on small parts of your pollution monitoring system to make sure it keeps working correctly. It also suggests doing a test afterward to be extra sure everything's okay.

Calvin Consulting specializes in crafting top-notch Continuous Emissions Monitoring System (CEMS) Quality Assurance Plans (QAPs) to ensure compliance and accuracy. Our 'how-to' manuals have received industry recognition and regulator approval in Alberta since 2007.

With a proven track record since 1999, Calvin Consulting offers certification, recertification, and major component replacement services. For specialized consulting services, including comprehensive plans, audits, and corrective action guidance, please contact us via email.

Clean air is our Passion...Regulatory Compliance is our Business.

Certification process for Continuous Emission Monitoring systems equipment:

Operational testing, performance specifications and recertification after major component replacements. Learn about quality control procedures and gain insight into other component replacements. That way you can maintain emission data accuracy and reliability.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

GPT-4, OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.