- Air Homepage

- Alberta Air Quality

- Air Quality Dispersion Modelling

- Different Types of Air Pollution

How to Understand Different Types of Air Pollution and Get Approvals

When factories and machines run, they release pollutants into the air, which we call emissions. Emissions change over time and under different conditions, leading to different types of air pollution. Knowing this helps us keep the air clean and safe. We want air emissions modelling made simple.

Your Guide to Industrial Approvals: Air Emissions Modelling - Which complex operational scenario could be hiding your facility's worst air pollution risk? Discover the essential modelling roadmap required by Western and Canadian regulators to get approvals and ensure clean air.

What kind of air pollution is there?

- Particulate matter (PM): Inhaled particles or droplets. PM comes in the form of dust, soot, smoke, and liquid droplets from construction sites, unpaved roads, fields, and fires.

- Acid rain and smog are caused by nitrogen oxides (NOx). Combustion engines, power plants, industrial processes, and vehicle emissions all emit nitrogen compounds.

- Sulphur oxides (SOx) can cause acid rain and respiratory problems. Burning fossil fuels like coal and oil, and smelting metal are what we associate with it.

- Organic chemicals that evaporate into the air are volatile organic compounds (VOCs). Paints, solvents, gasoline, and industrial processes emit benzene, formaldehyde, and toluene. They're the most common VOCs.

While there are many others, including metals, this short list introduces the most common ones. Here’s what we might need to address:

Wow! factory emissions vary a lot

Wow! factory emissions vary a lot- Variability of Emissions: Emissions can change in the short and long term due to different operating conditions or unexpected problems.

- Using Models: We use computer models like AERSCREEN to predict air pollution levels under various conditions, such as different factory capacities (25%, 50%, 75%, 100%) and during events like start-ups or shutdowns.

- Worst-Case Scenarios: It’s important to predict the different types of air pollution that happens during the worst-case scenarios, like equipment failures or unusual operations.

Steps for Approval and Assessment

- New Facilities and Renewals: When applying for new facility approvals or renewals, evaluate potential air quality impacts under various operating scenarios.

- Emission Limits: Facilities must calculate their emission rates using engineering principles and comply with set limits.

- Upsets and Shutdowns: Rare events like unplanned shutdowns can cause spikes in emissions. These need special consideration in the modeling process.

- Modeling Scenarios: Different scenarios must be modeled to ensure a thorough assessment, such as maximum emission rates, typical operational rates, and specific events like non-routine flaring.

Practical Steps for Accurate Assessments

- Estimate Emission Rates: Use design data, engineering estimates, or published emission factors to estimate emission rates.

- Model Different Scenarios: Model all project sources at their maximum rates, consider typical operational rates, and assess emissions during start-ups, shutdowns, and malfunctions.

- Annual Average Concentrations: For annual assessments, use typical emission rates without considering upset limits, focusing on regular operations.

Types, Impacts, and Alternatives to Air Pollution

Who would be interested in this?

It's great for anyone building new facilities or seeking approval for changes. To predict pollution levels, air quality assessments consider different operational scenarios, from full capacity to malfunctions. By knowing this, you can make informed decisions to minimize environmental impact.

Understanding air pollution and modeling emissions is crucial for:

- Keeping facilities in compliance with air quality standards.

- Protecting communities from pollution.

- Reducing the environmental impact of industrial operations.

Check out how British Columbia, Alberta, and Saskatchewan handle these issues in their air quality modelling guidelines.

Beyond Smog: Understanding Air Pollution in British Columbia

It's important to consider air emissions' variability over time when modeling them. Here's how it works:

Variability in BC's emission rates

Variability in BC's emission ratesImpact of Alberta's facilities on the air

It's important to show potential impacts under various operating scenarios when you're applying for approval for a new facility or a renewal/amendment. Here's what I mean:

- Emissions during stable operations. You should use Alberta's Annual Emissions Inventory Report Standard for existing facilities, and engineering principles for new ones.

- Emissions Limits: Facilities have emission limits, either facility-wide or per source. Calculate these rates using engineering principles and operational conditions.

- They happen rarely and produce more emissions than normal operations. The approval may or may not have a limit.

- Planned startup/shutdown: Infrequent events with prescribed procedures to reduce emissions. Unplanned events are upsets, not planned ones.

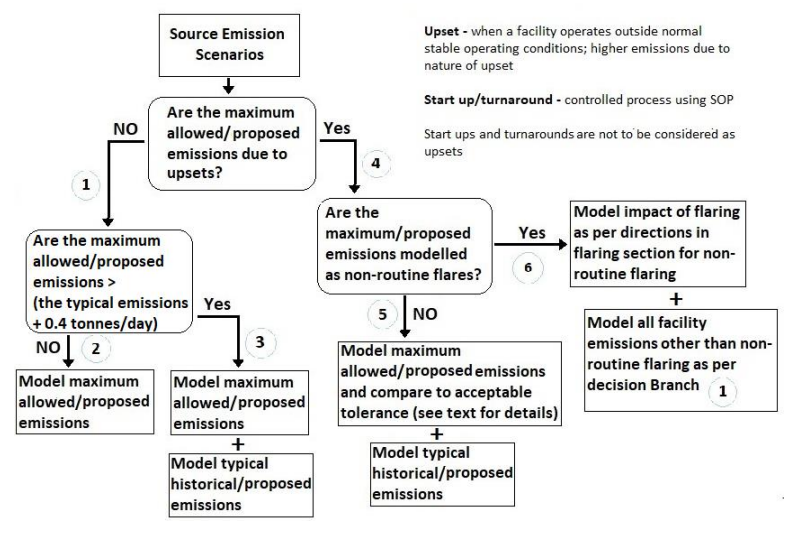

Remember to use representative maximum and typical emission rates. This flowchart, from the Alberta Guideline, you'll find guidance on determining emission scenarios for new projects and renewals/amendments.

This addresses different types of air pollution for new applications, renewals, and amendments.

This addresses different types of air pollution for new applications, renewals, and amendments.Air quality assessments for new facilities or developments should include these steps:

- Emission rates can be estimated using design or engineering estimates, or by using published emission factors.

- Assessment of Upsets and Differences: Find out if any project sources have maximum emission rates. If not, take one path; if yes, take another.

- Also, see if the proposed maximum emission rate exceeds typical rates by more than 0.4 tonnes.

Depending on the assessment outcome, different modeling scenarios are needed:

- Model all project sources at their maximum emissions.

- Model project sources with different maximum and typical emissions rates. Some emit at typical rates, others at maximum rates.

- During startup, shutdown, and malfunctions, assess the emissions.

- Find out if maximum emissions are from non-routine flaring.

- Follow a specific modeling approach if yes.

- Calculate annual average concentrations using typical emission rates for project and non-project sources without considering upset limits.

We've got examples to illustrate these steps, so you can make sure your air quality impact assessments are thorough and accurate.

Same logic applies to renewals or changes to approvals. The maximum emission scenarios should match the approved or proposed limits.

Emission rates are based on the average of the last three years, excluding abnormal years. Different methods can be used to determine stack emission parameters, but approval limits are the best.

Air quality models can't directly use emission limits from approvals, so conversions have to be spelled out. It's okay to model only during certain times if sources only operate during those times.

Different types of air pollution affecting Saskatchewan Skies

Modeling air emissions for a facility requires considering various scenarios:

Decision-making and the environment

Decision-making and the environmentAssume all operations are running at full capacity simultaneously, giving a conservative estimate. Consider remodeling if air quality standards are exceeded.

Consider factors like variable emission rates and intermittent sources when estimating operating emissions. Assess emissions during startup and shutdown. It might not be necessary to model if emissions don't increase significantly or happen frequently.

Emergency scenarios and malfunctions: High emissions during malfunctions or emergencies should be assessed, especially for facilities near communities. Give a reason for including these scenarios.

They help guide decision-making and mitigate risks by capturing different types of air pollution - potential impacts under different operating conditions.

Understanding Air Emissions: A summary of the Guide for you

The guidelines simplify air quality assessments for new facilities or changes to existing ones. They act like a roadmap for considering how much pollution a facility might create under various circumstances.

Why it Matters:

Air Quality and pollution levels can fluctuate depending on how a facility operates. We need to consider these variations to predict air quality accurately. Here are a few key points:

- Emission Rates: These change based on a facility's activity level. Imagine a factory running at full blast versus idling.

- Approval Limits: Facilities have limits on how much pollution they can release, set by permits.

- Modeling Scenarios: We use computer models to predict air quality. These models consider different "what-if" situations to get a complete picture.

Scenarios to Consider:

- Full Capacity: This is a conservative estimate, assuming everything is running at maximum power at once.

- Normal Operations: This reflects typical daily activities, with some equipment running more than others.

- Start-Up/Shut-Down: Emissions might be higher during these times, but may not happen often.

- Upsets (Emergencies): Unexpected equipment failures can cause high emissions. These are rare but important to consider, especially near communities.

The Outcome:

By considering these scenarios, air quality assessments can help:

- Make informed decisions: Knowing potential pollution levels helps choose the right path for a facility's operations.

- Minimize risks: Understanding worst-case scenarios allows for better planning to protect air quality.

- Remember: This is a simplified overview. There's more to air quality assessments, but this guide was meant to give you a good starting point!

This is what you might find in an Emissions and Dispersion Modelling Report:

1. Introduction - Reason for emissions evaluation under various for [Your Facility Name].

2. Emission Sources - Source-specific emission rates for all emission sources.

3. Modeling Scenarios - Emissions during normal operation, when the facility's at maximum capacity, during startup and shutdown, and unplanned events or malfunctions.

4. Dispersion Modelling - Pollutant concentrations at various receptor sites are predicted using a dispersion model (like AERMOD) with emission rates, terrain features, and meteorological data.

5. Compliance Assessment - Recommendations for reducing emissions based on comparison of predicted concentrations to prevailing objectives.

6. Conclusion - Findings and actions for regulatory compliance based on predicted on air quality impact.

Get expert air quality modeling for your industrial needs with...

Calvin Consulting Group Ltd.

Are you planning to build a new facility or manage an existing one? It's important to make sure your operation meets air quality standards. Calvin Consulting can help.

We're seasoned dispersion modelling experts with over 30 years' experience. With our help, countless industrial clients have made their way through approval processes and maintained compliance.

What makes Calvin Consulting different?

- A realistic picture of your facility's impact requires considering emission variability. We'll model normal operations, start-ups, shutdowns, and even malfunctions to make sure we're thorough.

- We have a team of Canada's top dispersion modellers. You can trust our knowledge and abilities because we've done modeling for clients and trained regulatory agencies.

- Streamlined process: From data collection to report generation, we've got you covered.You'll save time and effort with our clear, concise reports.

Peace of Mind for Your Operation and the Environment - With Calvin Consulting, you'll be able to work through air quality regulations with confidence. You can use our modelling to:

- Get your new facility or modification approved with a comprehensive air quality assessment.

- Maintain compliance: Make sure your existing facility operates within permitted limits.

- Optimize operations and reduce emissions with valuable insights.

Take advantage of our custom modeling services. With Calvin Consulting, you'll get unmatched expertise and personalized attention.

Get a helpful consultation with Calvin Consulting today.

Let's discuss your specific needs and how our air quality modeling services can help you breathe easy.

Clean air is our Passion...Regulatory Compliance is our Business.

Have you ever wondered how a factory's ups and downs affect air pollution?

This guide dives into the various scenarios that affect air emissions, so we can keep it clean, such as air pollution from new production facilities. A facility's operations can have a surprising impact on air quality, and scenarios range from daily work to unexpected emergencies.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.