- Air Homepage

- Alberta Air Quality

- Prevention of Air Pollution

- Emission Limits

Compliance and Impact Insights on Industrial Emission Limits and Schedules

Tracking and adhering to emission limits might seem painful, but they're crucial for environmental compliance. Maintaining air quality standards is also important.

Reporting emissions limits and operating schedules with the Compliance Clock - What's the time and hourly limit for every pollutant your facility releases? Learn how to document all your normal and upset emissions limits, along with your precise operating schedules, to avoid serious penalties.

Air quality impact

Air quality impactDocument normal and emergency limits, keep track of substance quantities and operating schedules, and you'll be able to make sure you're compliant and protect the environment.

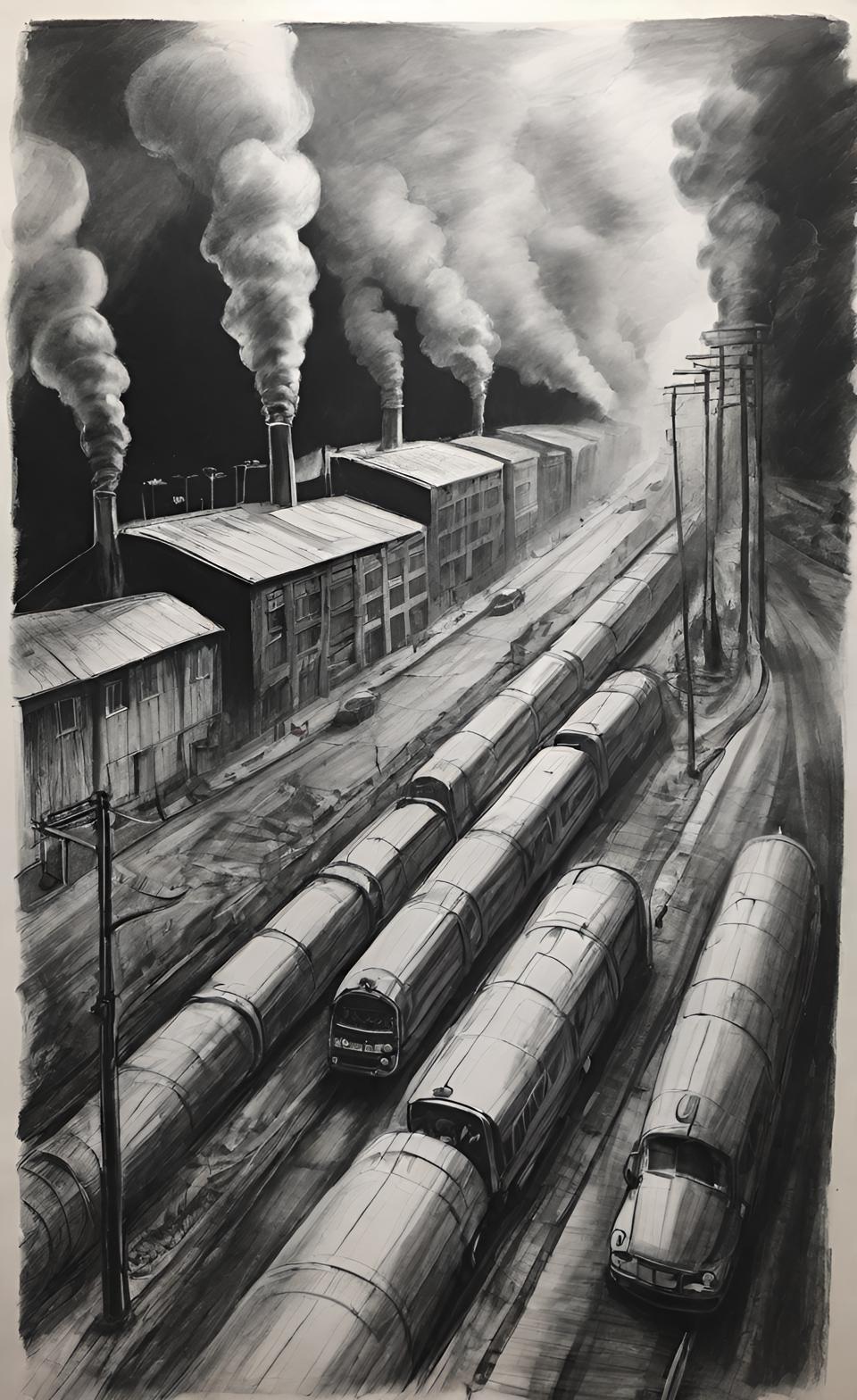

Pollution, violations, and other problems can arise if you don't follow these limits. Set a limit; stay within it. Industrial operations have to be good neighbours, operate sustainably, and be responsible. Protect air quality for present and future generations by minimizing your impact on the environment.

Here is an overview of the Alberta Annual Emissions Inventory Report (AEIR) process document, Sections 11 and 12.

Environmental compliance requires maintaining air quality standards and adhering to emission limits. Document normal and emergency limits, track substance quantities, and keep detailed operating schedules to keep your industrial operations compliant.

The proactive approach prevents pollution, violations, and other issues, ultimately protecting air quality. You can use this article to reinforce your commitment to minimizing environmental impact and make a big difference by maintaining compliance and sustainability.

Section 11.0 - Information about emission limits (Steps 11a - c)

The text focuses on gathering and recording emission limits and related information for industrial operations. Knowing what pollution limits affect you, keeping aware of limits during normal operations and emergencies and when different parts of your facility are emitting substances into the air are all part of this. These details will help you ensure compliance with environmental regulations and understand how the facility might affect air quality.

11.1 - In Step 11a, you find and list the pollution limits for your industrial operation.

Standards or authorities set these limits. During regular operations, you can't go over them. If it happens, report it on the AEIR. Take note of performance targets and emergency limits, too.

11.2 - Step 11b, Collect data on your industrial operation's normal emissions

There are limits on how much of a certain substance can be released. The substance, quantity, units, and any conditions or performance targets you need to know. By doing this, you'll stay within acceptable pollution levels. The AEIR form needs this information.

As an example, if there is an emission limit for nitrogen oxides from boilers, you need to specify that the substance is nitrogen oxides, the limit quantity is 58.0 kilograms per hour, and the units are kilograms per hour. Also mention any conditions (like "normal operating conditions") and performance targets (if applicable).

You need these details to make sure your industrial operation complies with environmental regulations.

11.3 - Step 11c, emergency or upset emission limits

During emergencies or upsets, these limits define how much of a substance can be released.

For example, if you have a Combined Boiler Control Stack with a PM2.5 (particulate matter) upset limit, you should specify that the substance is PM2.5, the limit quantity is 1.5 tonnes per hour, and the units are tonnes per hour. Also, mention any conditions (like "n/a" if not applicable).

You need this info to make sure that your industrial operation complies with environmental regulations, especially during unexpected situations. Maintaining air quality standards and preparing for emergencies is important.

Section 12.0 Steps 12a - c: Temporal Operating and Emitting Information

As important as your emission limits is your operating schedule. For a working facility, you need to log when it is up and running. Is it working all the time, 24/7? Or does it follow a work schedule, shutting down on weekends for instance? Submit this schedule so we all understand how much stuff it's letting out into the air and when.

12.1 - Step 12a, when are different parts of your industrial operation releasing emissions

Calculate air emissions with this info. For both point sources (like smokestacks) and non-point sources (like open areas), you'll fill out worksheets in the AEIR Form. You need these worksheets to figure out how your operation affects air quality.

12.2 - Step 12b, when and how parts of your operation operate and emit substances

Pollutants get released into the atmosphere during work hours, usually.

Here's how it works:

1. Operating schedule types:

- Continuous: These sources run 24/7 when the industrial operation is active.

- These sources operate occasionally during regular operations, but not all the time.

- Upset/Emergency: These sources only work during emergencies.

- Semi-Annual: These sources run a few times a year.

Release of pollutants that affect air quality

Release of pollutants that affect air quality2. Monthly and daily info:

You might use the same schedule as for continuous sources. For others, you need specific daily and monthly info. The daily info includes how many days a week the source runs, whether it runs on holidays, and its operating hours. The monthly info is how much the source operates each month, either in hours or percentages.

3. Imagine a factory boiler stack, for example. Use the factory's schedule if it runs all the time. You'd specify that in the form if it only runs in the mornings. Emissions can be tracked more accurately this way.

It's crucial for understanding how an industrial operation affects air quality.

12.3 - Step 12c, non-point sources and how they work.

It's important to know this because it greatly affects pollutants released into the air.

Similar to above, let's break it down...

1. Operating schedule types:

- Continuous: In an active industrial operation, these sources run all the time.

- Intermittent: They run a lot, but not all the time.

- In an emergency or unusual situation, these sources won't necessarily be emitting substances.

- A semi-annual event happens a few times a year or every few years.

Air Quality Impact of Emissions.

Air Quality Impact of Emissions.2. Monthly and daily info:

You might use the same schedule for continuous sources. For others, you need specific daily and monthly info. The daily info includes how many days a week the source runs, whether it runs on holidays, and its operating hours. The monthly info is how much the source operates each month, either in hours or percentages.

3. Another example: Imagine the loading/unloading process at a mine. You'd use the mine's schedule if it runs all the time. If it only runs after noon, you'd specify that. Emissions can be tracked more accurately this way.

4. If any part of a non-point source runs during a certain time, the whole non-point source is considered running (even if not all sources are running). The only thing we need is general temporal info.

Data like this helps operators and regulators understand how industrial operations affect air quality.

Ensure Air Quality Compliance: Expert AEIR Submission Consulting!

Calvin Consulting Group Ltd.'s Expert AEIR Submission Service maximizes compliance. Alberta's industrial facilities can rely on our comprehensive consulting service to submit accurate and timely emissions inventories.

The Calvin Consulting Group helps Alberta's industrial facilities submit Annual Emissions Inventory Reports (AEIRs) in compliance with the Environmental Protection and Enhancement Act (EPEA).

Calvin Consulting Group's expert consulting services can help your business submit AEIRs and comply with EPEA regulations. We believe in helping you navigate AEIR submissions, ensuring accurate reporting of emission limits, normal and emergency emissions, and operational schedules.

Facilities such as yours can streamline compliance processes, maintain air quality standards, and prepare for unexpected situations by entrusting us with AEIR submissions.

For reliable AEIR submission consulting, contact us at

You'll be glad you did. At Calvin Consulting,

Clean air is our Passion...Regulatory Compliance is our Business.

Tracking industrial activities is important.

To comply with environmental regulations and maintain air quality, you have to adhere to emissions limits. If your company identifies emission limits, collects good data, and plans operating schedules, you have a head-start. Keep in mind, you could get in trouble and even harm the environment if you don't comply. There's a good reason for emission limits.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.