- Air Homepage

- Alberta Air Quality

- Prevention of Air Pollution

- How to Measure Air Pollution

How to Measure Air Pollution: Official advice

In order to answer how to measure air pollution, we're quantifying emissions from industrial activities, normal rates, and maximum limits. These techniques provide reliable data crucial for environmental protection efforts because of their consistency and accuracy.

AEIR Quantification Guide: Measuring industrial emissions - How do you calculate your factory's annual, normal, and maximum pollution rates? Unlock the official, in-depth guide to choosing, applying, and getting approval for the precise scientific techniques needed to measure industrial air emissions.

Stewardship, reliability and beauty

Stewardship, reliability and beautyTransparency and accountability can be maintained in annual reporting by adhering to standardized methods. These practices aim to protect the environment and human well-being from pollution, ensuring a sustainable future for future generations.

This article is a summary of the Alberta Annual Emissions Inventory Report (AEIR) Standard, Section 15 and it explores the different methods used to measure air pollution from industrial sources in some detail. Consider the examples and the importance of accurate data for environmental stewardship.

We'll see how air pollution measurement affects environmental policies, public health, and sustainability. Think about how these methods contribute to a cleaner, healthier planet. Also, think about how you can apply the knowledge from the article in your own life, whether it's advocating for cleaner air policies, supporting eco-friendly initiatives, or just being more eco-conscious.

Some background on Measurement

Measuring emissions is a major part of understanding and managing air pollution levels, which affect people and ecosystems. We can reduce pollution by first measuring how much pollution facilities, vehicles, and power plants emit into the air.

Emissions need to be measured for several reasons:

- Monitoring emissions lets us identify pollution sources and protect public health. You can get respiratory, cardiovascular, and other health problems from air pollution.

- Measurements help us understand and reduce the environmental impacts of pollutants like sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter (PM).

- Government departments set air quality standards and emission limits to protect the environment and our health. Industries have to measure and report their emissions.

Some emit carbon monoxide (CO), SO2, and PM. With emission measurement techniques, the factory can track pollution levels, identify areas for improvement, and reduce its environmental impact, which might include smog or acid rain.

Monitoring air quality for real-time pollution data

Monitoring air quality for real-time pollution dataMethods of quantification

We have a few technologies for how to measure air pollution:

Continuous Emission Monitoring Systems (CEMS): They continuously measure and record emissions from industrial sources to ensure compliance. A CEMS measures and monitors gaseous emissions from refineries, power plants, incinerators, and other industrial facilities to give you direction of how to comply with provincial regulations.

Predictive Emissions Monitoring Systems (PEMS) can predict emissions levels using mathematical models and real-time process data, especially where direct measurements are hard or expensive. PEMS can estimate emissions and help you optimize processes based on operational data.

Estimates from Material Balance: This method calculates emissions based on inputs and outputs of materials in a process. It's used in situations where direct measurement is impractical. By accounting for all materials entering and leaving a system, we can estimate pollutants released.

Emissions vs. ambient air quality

Compared to emissions measurements, ambient air quality monitoring assesses the overall air quality in an area using these tools:

- Low-cost sensors: These monitor air quality in real-time. They can be used for community monitoring and public awareness.

- The Air Quality Index (AQI) monitoring stations measure pollutants and give you an overall air quality score. They're often run by governments.

- Using small kits, individuals and communities can monitor air quality and share data.

Tips for assessing local air quality

- Using low-cost sensors, you can monitor pollutants like PM2.5 (PM in smaller pieces) and ozone in real-time.

- Take part in local or national citizen science initiatives to monitor air quality.

- Check your local AQI reports to stay informed about air quality.

Emissions from industry and environmental health

Industrial emissions can have a negative effect on the environment. Pollutants like SO2 and NOx can cause acid rain, while high PM levels can lead to disease in people and animals. By measuring and then controlling industrial emissions, we can protect the environment and public health.

Emissions data in environmental models

Emissions data are needed for environmental models and public health studies. Scientists use the data to understand pollution sources and distribution, predict air quality trends, and assess pollution control. Pollution levels are also linked to respiratory diseases and premature deaths in public health studies.

Here is how the AEIR Standard delves into methods for quantifying industrial emissions.

Section 15: How to measure air pollution by identifying how much stuff is released

This step involves how to measure air pollution, how much certain substances are released into the air by factories and industries. We measure the actual amount released in a year, the normal amount, and the maximum amount. We can keep track of pollution with these measurements.

Our rules (as outlined in the AEIR Standard) explain how to measure these amounts. We can choose from a list of approved methods if the rules don't specify a method for a particular substance from a specific source.

Once we decide on the methods, we can figure out how much is released. We need to use the same methods every year, but if we want to change, we need permission (Section 15.6, below). There's also a process for using non-standard methods (Section 15.7).

15.1 - Calculating emissions with CEMS Monitoring

How do we figure out how much stuff is being released into the air? Calculate the actual yearly emissions, the normal emissions, and the maximum emissions.

We have a specific method for how to measure air pollution and calculating emissions for 2022, 2023, and 2024. It's mandatory in some situations, like when factories use Continuous Emissions Monitoring Systems on one piece of equipment to estimate emissions for identical equipment without CEMS. Monitoring pollution this way saves money by reducing redundancy.

Cost-effective and eco-friendly

Cost-effective and eco-friendlyWhen you report your emissions with CEMS, you select "AEIR Standard Annual Method". For CEMS Monitored and Identical Equipment emissions, here's the equation to use:

Total Annual Actual Emissions (TAEX) = (Emission Rate for CEMS Monitored Equipment * (1 - Load Difference)) per hour.

This means we calculate emissions every hour the equipment runs. In the same hour, the monitored equipment and identical equipment may operate differently due to load differences.

Here's how to calculate annual NOx (mixed nitrogen oxides) emissions from an identical boiler:

The monitored boiler and the identical boiler have data, like their operating hours, load, and NOx emissions. For each hour it runs, we calculate the NOx emissions using the formula. To get the total annual NOx emissions for the same boiler, we sum up all these hourly values.

Then we'll have representative data on emissions from similar equipment without having to install CEMS on each one. Keeping track of pollution is important and this shortcut helps with how to measure air pollution.

15.2 Emission rates (overall methods)

Let's talk about how we figure out emissions. Three ways of representing emissions need to be calculated: actual annual emissions, normal emissions, and maximum emissions.

In the first place, we use the best available information, methods, and data for how to measure air pollution in your specific industry. The industry needs to have accepted these methods.

We use the same methods as last year unless:

- This is our first time reporting.

- The previous year, we didn't meet reporting thresholds.

- The Director gave us permission to use different methods.

We use these rules to make sure we're consistent, but we're flexible too. We want accurate air pollution data.

15.3 - Methods for calculating annual actual emissions

Let's look at how we calculate how much stuff is released into the air each year. It doesn't always require direct measurements; estimates can work, too. Actual air emissions are the amount of a substance emitted from a source in a given year.

In this example of how to measure air pollution, we calculated 58.54 tonnes per year of NOx emitted from Stack A in 2022 using an emission factor (EF) and fuel data.

As listed above, we use the same methods unless it's our first report for this location, we didn't meet thresholds in the previous year, or we have written permission to do otherwise.

Quantification methods normally used include continuous monitoring, predictive monitoring, source testing, materials balance, and a few other less common ones. When necessary, estimation methods can be used instead of monitoring.

Air emission tracking for better skies

Air emission tracking for better skiesWhen the AEIR Standard doesn't specify a mandatory method, we choose the most appropriate method based on our situation. The Quantification Methodology Document is where we outline our chosen quantification methods. Here are a couple examples:

15.3.1. CEMS Annual Method: Continuous Emission Monitoring measures emissions constantly. Concentration, flow rate, and other factors go into calculating emissions. Calculate SO2 (Sulphur dioxide) emissions from Source Y using CEMS. SO2 concentration, molecular weight, stack gas flow rate, etc. Each hour, we can calculate emissions using this technology. Then we get the annual emissions by summing these hourly rates.

15.3.2. The PEMS Annual Method predicts emissions based on correlations between emission rates and monitored process parameters, like fuel consumption. PEMS example: Calculate annual PM2.5 emissions from Source Y. Fuel input rate is continuously measured. We know from previous testing that for every tonne of fuel, 14.55 kg of PM2.5 is emitted. Each hour, we calculate emissions. We get the annual emissions by summing these hourly rates.

Our ability to estimate emissions accurately depends on these methods when it comes to how to measure air pollution for understanding and managing air quality and environmental impact.

To figure out how much a substance is released into the air every year, we use a variety of methods. We use these methods to track and manage industrial emissions.

15.3.3. Annual source testing:

- What's it all about? To calculate the annual rate, you test emissions under normal operating conditions.

- We collect samples from exhaust stacks with probes, then use the data to estimate annual emissions.

- Here's the formula: Emissions = (Emission rate from tests) * (Operating time in hours)

15.3.4. Annual Materials Balance:

- What's is it? Emissions are calculated by comparing materials entering and leaving a process.

- We predict emissions by looking at the substances in materials.

- The formula is: Emissions = (Material input - Material output)

15.3.5. EF Annual Method for Each Site:

- What's it all about? Based on detailed knowledge of the industrial operation, this method uses specific emission factors.

- Emissions are calculated using an emission factor and activity data, which is more accurate.

- Here's the formula: Emissions = (Activity rate) * (Emission factor)

15.3.6. Published or general EF method:

- How does this one work? Organizations or agencies provide non-site-specific emission factors.

- It's based on an emission factor and activity data, but it's less accurate for specific operations.

- Here's the formula: Emissions = (Activity rate) * (Emission factor)

15.3.7. Annual Emission Estimation Model:

- What's it all about? Emissions are estimated using computer models and algorithms.

- To estimate emissions from different processes, complex algorithms and data are used.

15.3.8. Annual Engineering Estimate:

- What's is it? Emissions are estimated using engineering principles and judgment.

- Engineers use their expertise to make educated estimations, especially when others can't.

15.3.9. Method for Speciation Profiles:

- How does it work? To estimate specific species within emissions, this method uses chemical makeup profiles.

- Profiles calculate emissions of a specific substance in a mixture.

15.3.10. Annual Fugitive Monitoring:

- What's it all about? Emissions from fugitive and non-point sources are quantified using monitoring equipment.

- Sensors measure emissions from leaks or accidents.

15.3.11. The AEIR standard annual method:

- In the AEIR Standard, the Director prescribes this method. Look for Clause EIS 15-A in the Standard which indicates that: Whenever a factory or industry uses a CEMS, it needs to determine how to measure air pollution from other similar sources which don't have CEMS release. By comparing how much the CEMS-monitored source makes and how the unit is used the person in charge can figure out how much pollution each of the others makes.

15.3.12. Other Director-approved annual methods:

- In this case, the Director may approve a different method for some operations.

Each method serves a different purpose in quantifying emissions, depending on the circumstances. For environmental reporting and managing industrial impact on the environment, documenting how to measure air pollution with accurate emissions estimates are key.

15.4 - The AEIR Normal Emission Rate Method

How Do Emission Rates Work? In normal operation, a source releases an average amount of substances into the air. They're supposed to represent typical emissions under regular operating conditions. The rates are in tonnes per day.

Here's an example:

Imagine a factory with a smokestack (Stack A) that runs continuously. Stack A emits 1.8536 tonnes of PM2.5 per day. Using results from recent stack tests, this value is determined by converting from average hourly emissions.

Points to remember:

In normal rates, emissions are averaged over a full 24-hour period. Normal rates are calculated based on one-hour operation, assumed constant for 24 hours. Expected normal rates are reported for future release points. Sources that are temporarily shut down still have normal emissions rates.

Increasing emission reporting accuracy

Increasing emission reporting accuracyWhat's the deal with normal emission rates? A better understanding of typical emissions will enable regulators to make more intelligent decisions to protect the environment. It's always better to measure emissions than to estimate. however, professionals choose the best available (i.e., appropriate or usual) method if no specific method is mandated.

How often are normal rates updated? When the representative normal rate changes by more than 15%, the normal emission rates are updated. Regardless of the magnitude of change, annual or normal rates must be updated if actual rates exceed maximum approved rates.

Consistency check: Generally, normal rates should be lower than maximum rates and similar to annual actual rates. Again, rates shouldn't go over maximum.

Modeling regulatory dispersion: Modeling for not-yet-operating sources usually uses the "Single Annual Actual Normal Method", described below.

For understanding and regulating how to measure air pollution, normal emission rates are essential. Various methods are used to calculate these emissions during regular operations. Environmental protection depends on accurate reporting of these rates.

The Different Methods of Determining Normal Emission Rates - Environmental reporting relies on normal emission rates because they represent typical substance emissions. These rates can be calculated in a variety of ways:

15.4.1. CEMS: CEMS systems continuously measure emissions during normal operations. Calculate the normal emission rate by averaging these values.

15.4.2. Multi-sample average: This method involves multiple short-term source tests conducted under normal operating conditions. Normal emission rate is determined by the average of these results.

15.4.3. Using data from a single recent source test conducted under normal conditions.

15.4.4 Average of several annual actuals: Uses actual emission values from previous reports or inventories. You can get a more accurate normal emission rate by averaging multiple years. It's important to keep track of operating hours each year.

15.4.5 The single annual actual normal method: Establishes the normal rate using a recent annual emission value. Choose a year that reflects typical operations. Accounting for operating hours is an essential part of this method.

15.4.6 - The Engineering Estimate Normal Method: Used when CEMS, source testing, or annual actual data aren't available. It examines data, principles, and laws relevant to the source and is usually done by a professional engineer.

15.4.7 - The AEIR Standard Normal Method: The 2022-2024 inventory years might not have any specific normal methods. You can also use the "Manufacturer or Design Normal Method." Data availability and accuracy will probably help you determine which method to use.

15.4.8 Authorized in writing by the Director: The Director may approve a specific method for some operations. For the corresponding source and substance, that method should be used. AEIR Standard outlines how to get such approval.

These methods allow regulators and industries to monitor and manage emissions effectively by determining normal emission rates. Data availability, data representativeness, and regulatory considerations determine which method to use.

15.5 - Methods for calculating maximum emission rates

Next are some methods for calculating the maximum rate at which substances can be released into the air from industrial sources. Emission rates depend on emission limits, equipment specs, and other factors. Reporting on the environment depends on them.

These are maximum permitted air emissions, not necessarily what's released at a specific hour. For release points, they're reported in kilograms per hour. In this example, Stack A's maximum emission rate is 250 kg/hour if the approval limit is 250 kg/hour for SO2.

Various methods can be used to calculate these rates, including approval limits, equipment specifications, historical data, and engineering estimates.

15.5.1. Maximum Approval Limit

- Sometimes the limit for how much pollution a factory can make isn't the same as the maximum. Reasons for this difference include using different units or timescales, considering how associated units work, or combining limits from different sources. There are a few ways to figure out how much a facility can emit.

- The calculated maximum emission rates don't represent new or otherwise applicable limits for the industrial operation. As approval limits or source conditions change, they're updated to standardize emission rates.

- Generally, the maximum rate should be higher than the normal rates.

- There are a bunch of examples in the document, like how to calculate maximum emission rates using approval limits, concentration limits, intensity limits, and combined source limits.

- Under certain conditions, like when a specific piece of equipment is operating or isn't, or when using different fuels, there may be special limits applied.

- Emission rates are calculated using control limits for equipment efficiency or substance recovery.

- Limits based on amount of substance (mass) emitted: Some limits are based on how much a substance is in the effluent (concentration).

15.5.2. Maximum Design Method for Emission Limits

When we use the "Design Maximum Method," we use the most information about how to measure air pollution from a source to figure out its maximum emission rate. It usually comes from the manufacturer and tells us how much it can produce.

Emission limits: what to think about

Emission limits: what to think aboutChanges or special ways the unit works might need to be considered. For instance, a machine that makes 1000 liters of exhaust per hour can release up to 33 kilograms of a pollutant per hour if it releases 3.3 kilograms of the pollutant for every 100 liters.

15.5.3. Maximum Method based on data from the manufacturer

The "Manufacturer Maximum Method" also uses information from the manufacturer to find out how much pollution it can produce. It might be the most the machine can make in an hour.

When specification sheet says it can produce up to 3.8 tonnes per hour, that's the most it can make. Therefore, we use that number to declare out how to measure air pollution from the machine.

15.5.4. Emission rates based on historical maximums

It's like looking back in time to see what source made the most pollution. We can use different info, like how much it makes every year or the most pollution it has ever made.

This isn't always the best way because it doesn't always show how much the it can actually emit. We use this method if we don't have any other way to find out. To figure out the rate of emission in this case, we pick the highest pollution from the past few years.

15.5.5. Maximum from engineering estimates

This Engineering Estimate Maximum Method is when we figure out the highest amount the source could make using what they know about it works. All the information they have about the item under consideration is taken into account.

We also check similar machines for clues and make an estimate based on all that info. However, this method is generally applied only when there's no other way to figure out how the emission rate.

15.5.6 Standard Maximum Method for AEIR

The AEIR Standard Maximum Method doesn't yet have specific rules for figuring out how much pollution all units can produce. In the AEIR Standard, the Director might give extra ways to find out for cases where it's needed.

There's one additional way in the AEIR Standard at for the time being, explained in Appendix A. If you use it, indicate you're using the "AEIR Standard Maximum Method."

15.5.7 Director's Maximum Authorized Method

A company can use a different way to figure out how to measure air pollution from their sources if the Director approves.

Here, you indicate your need for using this special way applicable to the type of equipment and emission. The AEIR Standard explains how to get permission to use a alternative way. Once permission is obtained, say you're using "Method Authorized in Writing by the Director" on the forms.

This part of the document explains how to calculate the maximum emission rates from industrial sources for reporting, using different methods and examples. Reporting emissions to regulatory authorities is crucial for ensuring environmental compliance.

15.6 - Authorization Process for Changes to Atmospheric Emission Quantification Methodologies

This document outlines how to get authorization to change air emissions quantification methodologies in industrial operations. Reporting emissions should be consistent over time, and changes should only be made when necessary and if they improve accuracy. Here's a summary...

To determine annual actual air emissions rates, the person in charge of emissions reporting must use the same measurement methods, estimation techniques, and calculations as the previous year. It ensures consistency unless changes are genuinely needed.

Changes-to-method criteria

Changes-to-method criteriaAny changes to quantification methods need to be pre-approved by the Director. The responsible person submits a written authorization request via email to the Director and includes specific information outlined in the document.

In the event that changes are made without pre-authorization and included in the AEIR, the person will be required to resubmit the AEIR using the previous year's quantification method.

The Director evaluates proposed changes based on certain criteria. It's okay to make changes if:

1. Processes, equipment, or data availability have changed, so the previous method isn't working.

2. Previous estimations can be replaced by monitoring or measurement data. It's a lot more accurate now. We used an inferior method before.

Director's Decision: The Director reviews the request and emails the industrial operation his decision. Alberta Air Emissions Inventory Team usually handles this at the technical level.

Changes to multiple quantification methods can be submitted in one request, as long as each change includes the required information. And if it's the first time the industrial operation is reporting under the AEIR Program, changes to quantification methods don't need pre-approval.

For applicable cases, Director-specified methods must be used without pre-authorization when they're introduced in future AEIR Standards. Quantification Methodology Document and AEIR Form should document these changes.

Changing normal and maximum emission rates doesn't require pre-authorization, and they don't have to be revised every year. Over time, these rates should represent typical and maximum emissions.

Modifications due to Approval Limits: Changes in quantification methods for maximum emissions rates caused by changes in approval emission limits or the addition of applicable emission limits don't need pre-authorization. However, be sure to document these changes in the Quantification Methodology Document and the AEIR Form.

15.7 - Getting Authorization to Use Non-Standard Air Emission Quantification Methods

This part of the document explains how to get authorization to use non-standard quantification methods to estimate annual actual, normal, and maximum emissions. Here's a quick summary:

Information about method alterations

Information about method alterations- The document provides standard methods for calculating emission rates, covering a variety of scenarios that apply to industrial operations.

- Methods not covered by the standard methods: In rare cases, the person responsible may need to use methods not covered by the standard methods.

- Non-standard quantification methods require pre-authorization from the Director when they're needed. Send an email to emissions.inventory@gov.ab.ca. It needs to include specific info.

- Unauthorized Use: If pre-authorization for non-standard methods isn't obtained, the facility must use the standard quantification methods. A person responsible for the AEIR will have to resubmit using standard methods if unauthorized non-standard methods are used.

When requesting non-standard methods, the person responsible must provide:

- A description of the release point or non-point source, the associated units/processes/equipment, and the substance.

- An explanation of why standard quantification methods aren't appropriate.

- Information about the requested quantification method.

- An estimate of the impact of using the requested method on substance emissions for the release point or non-point source, if available.

- An estimate of how the requested method will affect the emissions of the entire industrial operation.

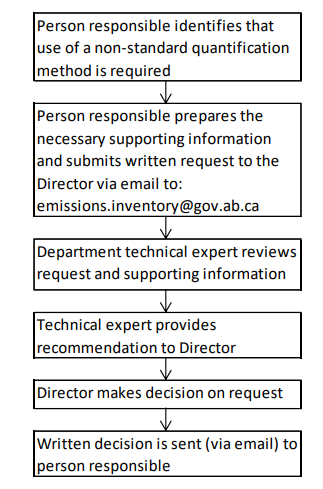

Director's Decision: The Director reviews the request for non-standard quantification methods and emails the industrial operation the decision. The flowchart in this figure shows the process.

Figure 7 from AEIR Standard

Figure 7 from AEIR StandardNon-standard method requests are usually handled by the Alberta Air Emissions Inventory Team.

Requests for multiple non-standard quantification methods can be submitted in one request to the Director, as long as each request includes the required supporting information. You could combine requests for NOX emissions from Stack A and SO2 emissions from Stack B, for example.

Basically, this document outlines how to get permission to use non-standard quantification methods for how to measure air pollution in Alberta when the standard ones don't work.

Emissions Inventory Reporting by Calvin Consulting Group Ltd.

Do you have an Environmental Protection and Enhancement Act (EPEA) approval in Alberta? You probably know that an accurate Annual Emissions Inventory Report (AEIR) is required. Our firm specializes in guiding facilities like yours through complicated processes.

Choose us!

- Our expertise in AEIR Standards ensures your submission meets regulatory requirements.

- Our team uses the most appropriate quantification methods outlined in the AEIR Standards, which may include continuous monitoring, source testing, materials balance, and engineering estimates.

- No two industrial facilities are alike, so we tailor our approach to meet your needs, which includes calculating annual, normal, and maximum emissions.

- Quantification Methodology is meticulously documented as required by Alberta Environment and Protected Areas.

- Director-approved methods: We seek approval for non-standard quantification methods when necessary. The request will be submitted correctly and efficiently to the provincial department.

- A quick turnaround time is achieved through our consultation process. We handle every step with precision if non-standard methods require written authorization.

We can assist you in preparing your AEIR submission by contacting us at:

Let's use correct techniques ensure accurate reporting and environmental compliance.

Clean air is our Passion...Regulatory Compliance is our Business.

It's hard to measure air pollution from industrial sources.

To calculate annual emissions, normal rates, and maximum limits, you can use Continuous Emission Monitoring Systems (CEMS) and other techniques. To make sure you submit reliable information to the provincial database, these methods focus on accuracy and consistency.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.