- Air Homepage

- Alberta Air Quality

- Continuous Emission Monitoring Systems

- Quality Assurance and Testing Services

Quality Assurance and Testing Services: Best ways to guarantee emissions monitoring accuracy

Here, you can explore Continuous Emission Monitoring Systems (CEMS) with a comprehensive guide on quality assurance and testing services. I'll introduce rigorous procedures that ensure accurate environmental measurements from gas analyzers, temperature sensors and others. The full details are provided in the Alberta CEMS Code, Section 6.

Get a bit about gold standard methods, calibration drift tests, and linearity assessments that are essential to evaluating CEMS accuracy. Different analyzers are tested with low and high-level gases, ensuring their reliability. Maintaining accurate emission monitoring systems, which are critical to environmental protection and regulatory compliance along with complex testing processes become more straightforward with this guide.

Companies who bring you quality assurance and testing services examine your pollution monitoring system (CEMS) to make sure it's performing as it should.

We start with a couple of Emission Monitoring Case Studies

Power Plant Accuracy Case Study:

- Regulators fined a big power plant for inaccurate emission readings.

- Plant operators implemented a comprehensive quality assurance program, including calibration drift tests and linearity assessments.

- Within six months, their emissions readings improved by 15%, reducing fines.

Enhancing Reliability in Chemical Manufacturing:

- Unreliable emission monitoring systems caused frequent downtime at a chemical manufacturing facility.

- QA service provider conducted biannual audits and implemented a maintenance schedule.

- Reliability of their emission monitoring systems increased by 20%, reducing downtime and ensuring compliance.

Emission Monitoring Self Testing

Emission Monitoring System Assessment Checklist

- Regular calibration: You have to do seven calibration drift tests in a row. Gas analyzers should be tested with both low- and high-level gases.

- Check the linearity of the analyzer across its entire measurement range.

- Using portable analyzers, compare measurements with CEMS every two years.

- Gas analyzers must meet accuracy and drift limits.

- Testing for orientation sensitivity: Analyze flow analyzers.

- Analyze flow analyzers for orientation sensitivity on a regular basis.

Quality Quiz: Does Your System Meet Standards?

Calibration Frequency:

How often do you perform calibration drift tests?

A) Weekly

B) Monthly

C) Annually

Linearity Testing:

Do you conduct linearity tests for your gas analyzers?

A) Yes

B) No

Audit Schedule:

How frequently do you conduct biannual audits?

A) Twice a year

B) Once a year

C) Never

Performance Specifications:

Do your gas analyzers meet performance requirements?

A) Yes

B) No

Maintenance Routine:

Are your emission monitoring systems regularly maintained?

A) Yes

B) No

Scoring:

Mostly A's: Your system is likely meeting quality standards.

Mostly B's: Your system may need some improvements.

Mostly C's: Your system requires significant attention to meet quality standards.

Your emission monitoring systems can be more accurate and reliable with these steps and tools. To help you achieve these goals, Calvin Consulting (see below) offers comprehensive quality assurance and testing services.

What quality assurance and testing services must do...

These are like rules to make sure your CEMS is working. Here's what they look like:

- It's mandatory to have gas analyzers for sulfur dioxide, nitrogen oxides, and others, and they have to meet certain rules called "performance specifications."

- If your CEMS measures sulfur dioxide, it should be within 10% of the real amount, and it shouldn't drift too much (change too quickly).

- Your CEMS measures different gases.

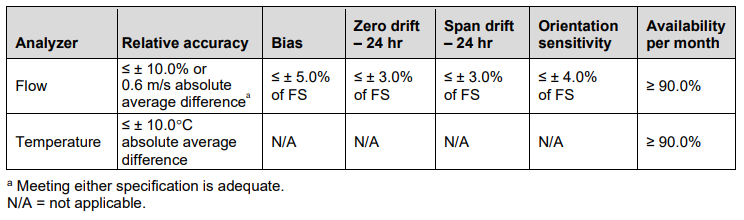

Accuracy rules for gas analyzers

Accuracy rules for gas analyzersHere's an alternative:

- It's okay if you can't meet the standard rules if your emissions are very low (less than 50ppm).

- It's easier to meet these rules, but you still have to be accurate.

- Flow analyzers, opacity analyzers, and temperature sensors:

- Tables 6 and 7 have rules for opacity analyzers, flow analyzers, and temperature sensors.

- Analyzers measure how much smoke or dust is in the air from a chimney, and they shouldn't drift too far from the standard.

- Flow analyzers and temperature sensors make sure gases flow through your system, and they have their own accuracy rules.

Monitoring systems:

- Tables 8, 9A, and 9B in the CEMS code list the rules for other systems that measure mercury, ammonia, ethylene, and ethylene oxide.

- The rules tell technicians who provide quality assurance and testing services how accurate your measurements should be and how much they can drift.

This section explains how to make sure your pollution monitoring system measures things correctly. It's like a quality check to make sure your system works correctly.

Accuracy

There's a lot of talk in this text about quality assurance and testing services and making sure emissions measurement equipment is accurate. Here's how it works:

- CEMS (Continuous Emission Monitoring System) measures emissions like gases released into the air.

- They use a gold standard method to make sure CEMS is working right.

- Gases are used in the test, including EPA Protocol Gas, which acts as a reference. CEMS is checked against these known gases to see if it's accurate.

Accuracy standards

Accuracy standardsAlso, we need to do a "calibration drift test" for seven straight days. Over time, providers of quality assurance and testing services check if the CEMS is still accurate.

Experts test different types of analyzers that measure different things. They use low and high-level test gases to make sure the analyzer works. They fix it if it's not.

The analyzer also has a "linearity test" to make sure it responds correctly across its entire measurement range. To make sure it works well in different situations, this is essential.

As an alternative way to check the CEMS, they talk about "alternate biannual audits." Using a portable analyzer, you can compare its measurements with the CEMS.

The CEMS is considered "out-of-control" if any of these tests fail. In essence, this detail is about how quality assurance and testing services test and calibrate environmental monitoring equipment to make sure it's accurate and reliable. Like making sure your scale measures your weight correctly, but for emissions.

Other tests for accuracy

The Relative Accuracy and Bias Test (RATA) for Continuous Emission Monitoring Systems (CEMS) is discussed in this text. For each run, testers need to collect at least 30 minutes of data.

To see how well the CEMS matches the reference method, we calculate something called "relative accuracy." Also, they check for bias, which is systematic error.

CEMS that don't meet accuracy and bias standards are considered "out of control" and need to be fixed.

To protect the environment, emission monitoring systems need to be accurate and reliable. This is where good quality assurance and testing services come in handy.

Orientation Sensitivity Test for Flow Analyzers

Here's a test for flow analyzers, which measure gas flow.

The test checks how sensitive a flow monitor is to changes in its orientation (position) when measuring gas flow. The table below shows how accurate the measurements remain when the flow analyzer is oriented differently. Here are a couple of specific points:

6.2-TT: To certify these flow analyzers, the person in charge needs to perform the "orientation sensitivity test" mentioned in 6.2-UU. It's important for analyzers that are affected by how they're positioned, like differential pressure sensors. If the flow analyzer isn't affected by its orientation, then this test doesn't apply, and the analyzer can be installed as directed by the manufacturer.

Quality assurance and testing services need to do the following to test the flow analyzer orientation sensitivity:

- Make sure the gas flow is stable before you do the test.

- In increments of 5 degrees, rotate the sensor in the gas flow by specific angles.

- Take a picture of how the sensor reacts at each angle.

- Try different flow rates.

- You should do this test at different flow rates: low, medium, and high.

After testing in 6.2-UU, make sure the analyzer meets the performance criteria in this table about its sensitivity to orientation changes.

Watch out for these details

Watch out for these detailsIndustrial facilities use CEMS to monitor emissions. RATA makes sure these systems are accurate and unbiased. It's like a quality check for the whole system.

During a RATA, you might compare CEMS data with a reference method. Also, check if it meets certain performance standards. Ideally, this test should be done under normal operating conditions, like when the facility is using its usual fuel and running normally.

Because the test needs to reflect real-world conditions, one can't fix or adjust the CEMS before or during the test. You can do regular maintenance, though.

Those of us who provide quality assurance and testing services need to collect samples at different points if the gas flow inside the monitoring system is uneven or not verified. They can just sample at one point if there's no uneven flow.

Then we can measure flow at different load conditions, like low, medium, and high loads. When comparing data, you should also consider moisture, pressure, and temperature the same way in the CEMS and reference method.

Audits and Quality Assurance Plans by Calvin Consulting!

Do you make sure your pollution monitoring systems comply with Alberta Environment and Protected Areas (AEPA) standards? A must for all industrial facilities in the province, Calvin Consulting Group Ltd. offers cutting-edge Quality Assurance Plans (QAP) and Audits for Continuous Emissions Monitoring Systems (CEMS).

We do the following:

- CEMS audits are required annually to ensure compliance with the Alberta CEMS Code and QAP.

- When necessary, our audits uncover discrepancies and guide you through corrective action planning.

- As experts in emissions testing, we provide expert assistance in complying with regulations.

Whether you need gas analyzers, flow monitors, or temperature sensors, we've got that covered. During our audits, we conscientiously examine monitoring systems to ensure that emissions are measured accurately and efficiently.

Let's work together to protect the environment. Get in touch with Calvin Consulting at...

...to elevate your emissions monitoring!

Clean air is our Passion...Regulatory Compliance is our Business.

Detailed testing and quality assurance procedures for Continuous Emission Monitoring Systems (CEMS), which may include gas analyzers, temperature sensors, and more.

The guide provides methods for making sure you get accurate environmental measurements needed for monitoring emissions and safeguarding the environment. Tests range from performance specifications to calibration drift tests.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

GPT-4, OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.