- Air Homepage

- Alberta Air Quality

- Air Quality Audit

- Quality Control and Quality Assurance

Quality control and quality assurance audit for ABC Airshed's monitoring 'Station 1'

In the story that follows, this airshed's station had a mix of successes and areas for improvement. Important items met standards, while less-critical ones needed improvement. The audit examined equipment, safety protocols and documentation. Alberta Environment and Protected Areas (AEPA) eventually acknowledged corrective actions, closing the audit. In-depth quality control and quality assurance helps ensure solid air quality data which supports a comprehensive environmental monitoring and public health assessment.

Breathing Easy at Station 1 - QC Wins and Quick Fixes - A hidden hero station silently watches our air, facing its ultimate test in a nail-biting audit that uncovers triumphs and tiny tweaks to keep our skies safe. Discover the action-packed world of ABC Airshed's Station 1, where precision meets passion for data you can trust.

This ABC Airshed monitoring station is deemed reliable because of the audit's systematic approach. The article below outlines the recommendations provided in the appendices of Chapter 8 of Alberta's Air Monitoring Directive (AMD).

Here is an article that summarizes the main body of Chapter 8, which provides details on ambient air quality audits.

Appendix A - Sample Audit Report

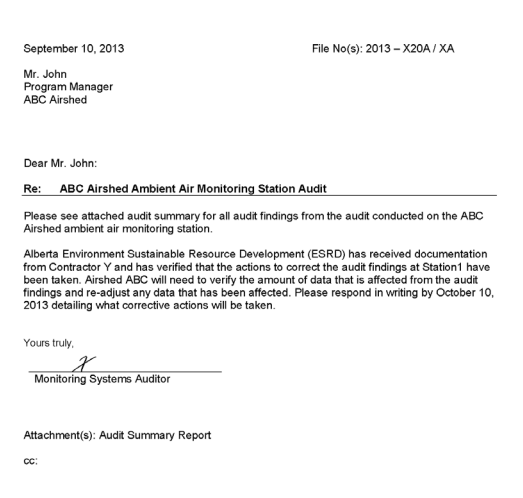

You'll probably cover these points in the cover letter you submit with the report:

- ABC Airshed's ambient air monitoring station got audited.

- As a result of the audit findings at Station 1, Alberta Environment Sustainable Resource Development (ESRD), now known as Alberta Environment and Protected Areas (AEPA) confirmed that corrective actions had been taken.

- Any data affected by the audit needs to be checked and fixed.

- By the end of the year, the agency demanded a written response detailing corrective actions for this situation.

The initial correspondence took a format like this:

Basically:

- ABC Airshed was audited.

- The network was audited for 22 parameters.

- Station 1 is the focus of the audit summary.

- Passed critical parameters like analyzers and meteorological parameters.

- There's room for improvement on some non-critical parameters.

- The station was checked for equipment and environmental conditions, and some things need to be fixed.

- Items like flow, leaks, wind speed, and direction were assessed.

- Safety and documentation were also taken into account.

- The audit identified areas that are okay, need improvement, or passed certain criteria.

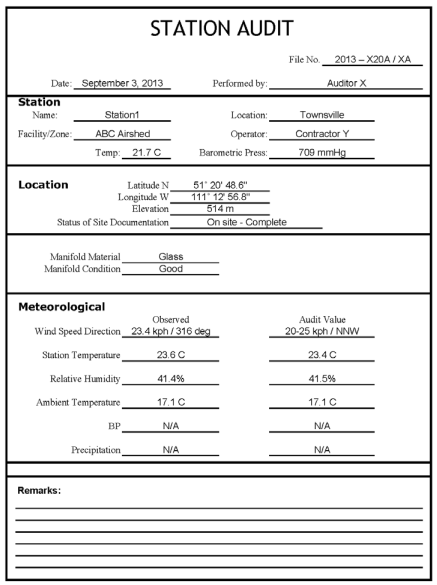

Here's a sample of the Station Audit Form:

What happened here?

- Auditor X conducted the audit on September 3, 2013.

- Contractor Y runs the station in Townsville.

- During the audit, it was 21.7°C and 709 mmHg barometric pressure.

- Station coordinates are 51° 20' 486" N and 111° 12' 56.8" W, with an elevation of 514m.

- The site documentation was reviewed and found to be good.

- Manifold material is glass, and it's in good shape.

- We observed and compared meteorological parameters like wind speed, wind direction, station temperature, relative humidity, ambient temperature, and precipitation.

- Observed values generally match audit expectations.

- The audit summary doesn't mention any specific issues or concerns.

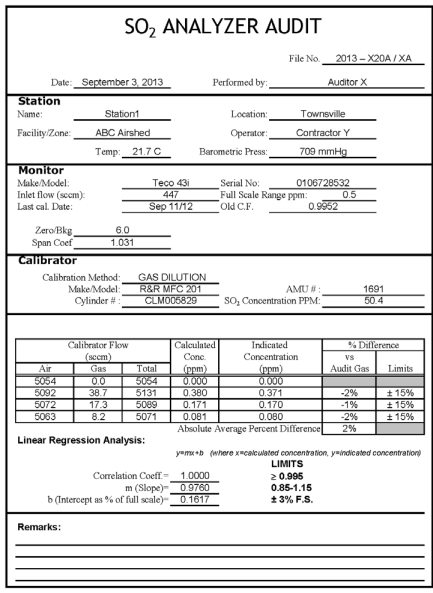

This is a form for one of several analyzers that were audited.

An audit summary for a SO2 (Sulfur Dioxide) Analyzer at Station 1 in ABC Airshed.

- Auditor X conducted the audit on September 3.

- It's a Teco 43i with serial number 106728532.

- It was 21.7°C and 709 mmHg during the audit.

- September 2012 was the last time the analyzer was calibrated.

- Calibration flow was 447 SCCM.

- Gas dilution was used with an R&R MFC 201 calibrator with cylinder number CLM005829 for calibration.

- Results of the audit compared calculated concentration, indicated concentration, and percentage difference.

- We did a linear regression analysis, showing correlation coefficients and slope and intercept limits.

- There was an average percentage difference of 2%, which is acceptable.

- During the audit, there weren't any specific issues or concerns with the SO Analyzer.

Audit of TEOM:

- A TEOM (Tapered Element Oscillating Microbalance) at Station 1 was also examined for quality control and quality assurance that same day.

- TEOM audits check temperature, barometric pressure, sampler setup, and current readings.

- Performance is measured by flow rates, temperature, pressure, and leak checks.

- The form mentions that the TEOM heads are clean, and that a leak was fixed on September 12.

- Also included is a Station Performance Audit Summary for NO, CH4, PM10, TSP, BTEX, and meteorological conditions.

- Data acquisition, system components, and wind equipment are discussed, as well as the general condition of the station and equipment.

Contents of the letter of closure for this sample case is also included in Appendix A:

- It's a response to the ABC Ambient Air Monitoring Station Audit Closure.

- A letter dated October 28, 2013 has been received and reviewed.

- AEPA is satisfied with the actions mentioned in the letter.

- Based on the information in the October 28th letter, ESRD considers the audit closed.

Appendix B - Quality Control and Quality Assurance Criteria

This section outlines the criteria for assessing the performance of different air quality analyzers during an audit. Here's what you need to know:

Analyzers that run continuously:

- Criteria for failure include regression analysis ranges, correlation coefficients, and deviations from the audit gas.

- Even marginal results prompt investigation to avoid failure in the future.

Assessing air quality equipment to make sure it's accurate.

Assessing air quality equipment to make sure it's accurate.Particle Analyzers (TEOM):

- Temperature sensor difference, leak check limits, flow audit differences, and pump on-time are all criteria.

- Particulate loading can lead to audit failure, so maintenance is important for quality control and quality assurance.

Other analyzers:

- If the outputs of meteorological and other analyzers deviate more than 15% from the audit reference, they fail.

- There are specific failure criteria for wind direction and speed analyzers.

- If operating parameters are outside specified limits, an analyzer with no calibration standards is considered failed.

System of calibration:

- There are similar failure criteria, including regression analysis, correlation coefficients, and deviations from calibration gas values.

Gas for calibration:

- The calibration gas fails if the concentration is more than 5% off.

A few general notes:

- The results are marginal, so we're looking for ways to improve them.

- Documentation and standard operating procedures (SOP) are key.

- Deviations from the criteria could lead to improvement or audit failure.

- Air quality monitoring equipment has to meet these criteria to make sure it's accurate.

Appendix C - Ambient Air Monitoring Audit

On-Site Checklist

During an audit of an ambient air monitoring station, this document serves as a checklist. During the quality control and quality assurance audit, analyzers, monitors, and sensors are identified and addressed in real-time. These are the main points of the checklist, which is divided into various sections:

1-Audit Calibration System Initial Checks:

- Check flow set points, concentration calculations, and plumbing connections.

- Make sure the audit gas cylinder regulator has been properly evacuated.

- Verify the zero-air system is working and compare the audit zero-air source to alternative sources.

2-Initial Checks - Audit Calibration System:

- Make sure the audit calibrator generates sufficient flow.

- Make sure the plumbing connections between the calibrator and analyzer are intact.

- Perform necessary comparisons and ensure proper operation of the zero air system.

Checking out the equipment on site

Checking out the equipment on site3-Audit of Ambient Air Monitoring - Onsite Checklist (Secondary - Analyzer Systems Checks):

- Make sure the analyzer is set to sample ambient air.

- The sample filter should be checked for condition and seating.

- Make sure the sample lines are clean and the connections between the analyzer signal output and the sample lines are tight.

4-Audit of Ambient Air Monitoring - Onsite Checklist (NO2 Audit Calibration - GPT Points):

- Include O3 flow in the total dilution flow.

- Maintain stable feedback readings for the O3 generator and NOx channel.

- Verify that NO/NOx has not shifted.

5-The two most recent calibration reports are as follows:

- After changing the source cylinder, verify that calibration responses are consistent.

- Align the analyzer test parameters with the last calibration observation.

6-Checks of the network:

- Ensure that other analyzers of the same type passed.

- Look for any undesirable trends or indications in recent historical data.

7-Checks of the station operator's system:

- The calibration system of the station has reintroduced calibration points.

8-System Particulate:

- Flows should be compared with those from another flow meter.

9-Onsite Checklist for Ambient Air Monitoring (Wind Sensor):

- Verify that the wind sensor orientation mark is visible.

In conclusion:

- Auditor and station operator will agree on an action plan if the checks do not provide conclusive evidence, possibly involving a return to the audit facility.

- To maintain accurate and reliable air quality data, this checklist ensures a thorough inspection of the monitoring station's equipment during an audit.

Appendix D - Ambient Air Monitoring Audit

Data Review Checklist

Checklist for auditing ambient air monitoring stations to ensure accuracy and reliability. Here's what you need to know:

Issues to be addressed:

- Analyze or calibrate the problem.

- Find out when the data might have been affected.

Calibration review:

- Make sure multipoint calibrations are up to date every month.

- Compile raw data files without any corrections.

Validating the data:

- Analyze changes to the automatic daily span and zero responses.

- Analyzer response and noise levels should be checked.

- Check logs for station events and operator activities.

Review of the calibration system:

- Check the calibration system's history for problems.

- Check the monitor range and output signal of the analyzer.

- Check calibrations against standard operating procedures (SOPs).

Calibration system checks for quality control and quality assurance:

- Check the calibration system's operation and maintenance logs.

- Make sure the flow meter and calibrator are compliant with the manufacturer's specs.

- Make sure the calibration system meets audit and AMD standards.

- Check the calibration gas concentration against a reference standard.

- Replace scrubber materials if they're worn out.

Corrections:

- Identify and document the plan for data correction.

By thoroughly reviewing and validating the data and making sure the instruments and calibration systems work, this checklist ensures the quality of air monitoring data.

How can we help?

Providing air quality monitoring and audit consulting services under the Alberta Environmental Protection and Enhancement Act (EPEA) Approvals, Calvin Consulting Group Ltd. (CCGL) provides expert Quality Assurance Plans (QAP) and audit consulting services for industrial facilities. According to the Air Monitoring Directive (AMD), facilities have to have a QAP that gets audited every three years.

Our efficacy has been proven by recent audits for various industrial sites. Alberta Environment and Protected Areas (AEPA) has confirmed our corrective actions on these occasions. Our team assesses parameters, equipment, and environmental conditions. Accurate data is ensured through the use of our comprehensive audit reports, including relevant analyzer assessments.

Get in touch with us at...

...to elevate your air quality reporting standards.

Here, the hypothetical ABC Airshed's Station 1 undergoes a comprehensive audit, assessing 22 parameters.

While critical parameters passed, lower-priority aspects needed work. The audit covered meteorological conditions, equipment checks and safety concerns. Alberta Environment and Protected Areas (AEPA) confirmed satisfaction with corrective actions, ensuring the audit was successful.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.