- Air Homepage

- Alberta Air Quality

- Prevention of Air Pollution

- Stuff in the Air

Monitoring, Insights, and Solutions for Stuff in the Air

Is this for you? Probably if you're concerned about stuff in the air and fit into one of these groups:

- Environmental Regulators who like clear guidelines for regulatory compliance.

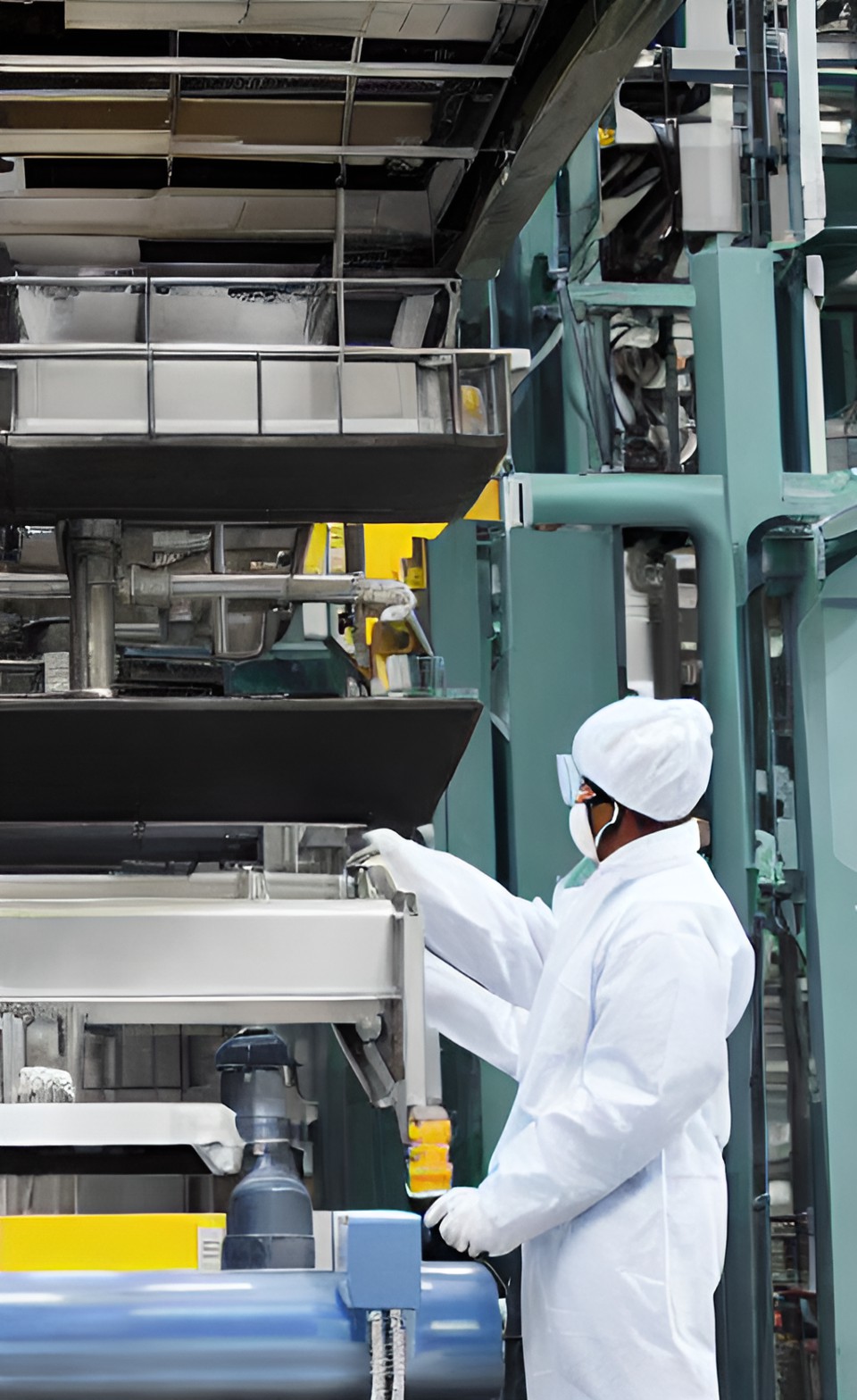

- Industrial Operators who need an introduction to source monitoring, accurate reporting, and mitigating their emissions.

Pollution Tracker: AEIR Compliance Monitoring - Are you tracking every single pollution source at your facility, from the main stacks to those sneaky leaks? Find out what you need to report to the government to prove that your air is clean and stop risking non-compliance (and its penalties.)

Details on release data collection

Details on release data collection- With a little more info on data collection, analysis, and interpretation, environmental scientists will be able to assess pollution levels a little better, helping us develop strategies for improving air quality.

The main point here is to show the impact of source monitoring on the control of pollution levels in industrial operations, how Continuous Emission Monitoring Systems (CEMS) and stack sampling work and how to use the data in calculating pollution rates. Details include:

- what data is needed

- how to fill out the Annual Emissions Inventory Report (AEIR) form

- why monitoring non-point sources is important

- monitoring methods

- substances or parameters monitored

- monitoring frequency, duration, and sampling dates.

Also, I outline where to put source monitoring and non-point source info in the AEIR Form. These instructions are spelled out in detail in Section 13 of the AEIR standard.

Glossary of terms

- Continuous Emission Monitoring Systems (CEMS): Equipment that continuously measures pollution. Like a health tracker, factory emissions are tracked.

- Stack Sampling is Analyzing pollutants, stuff in the air released from a factory's smokestack.

- Non-Point Sources includes Pollution that doesn't come from a single place, like smokestacks. Storage tanks, ventilation systems, or equipment leaks are examples.

- Fugitive Emissions: Unintentional leaks of gases or vapors from industrial equipment, like valves, pipes, or storage tanks. These sneaky emissions escape without being part of the main exhaust.

- Quantification Methodology Document (QMD): Explains how emissions are estimated without direct measurements. The methods and reasoning behind calculating pollution levels are explained.

- A report detailing all pollutants released into the air during the previous year is called an Annual Emissions Inventory Report (AEIR). Like a pollution diary.

- Monitoring frequency - for checking emissions are typically daily, weekly, or quarterly.

- Monitoring Duration - Monitoring emissions for three hours during each sampling session, for example.

- An industrial site monitors pollution in emission zones. An industrial site monitors pollution in emission zones.

- Schedule 1 and Schedule 2 substances have to be monitored and reported. There's usually ammonia or particulate matter.

- The Air Monitoring Directive (AMD) outlines Alberta's rules and guidelines for monitoring and reporting emissions.

- Pollution is regulated by Alberta's Environmental Protection and Enhancement Act (EPEA), which requires industries to report their impact on the environment.

- The monitoring of pollutants coming from specific locations within an industrial facility, like smokestacks or vents constitutes source monitoring.

- Assigned Emissions: When actual measurements aren't taken, emissions are "assigned" based on standard values from a reference library.

13.0 - Source Monitoring Information (Steps 13a - c)

Let's jump right in.

13.1 - We Introduce Source Monitoring in Step 13a

Monitoring what's coming out of industrial operations, like factories. Here's what you need to start:

- How does Source Monitoring work? It's like checking the factory's vitals. CEMS, stack sampling, and leak detection help you figure out what kind stuff in the air will we see. We can use this to determine how much pollution there is.

We need source measurements

We need source measurements- What's the point? Data from source monitoring is gold! It helps us calculate how much pollution comes from big sources and even those sneaky smaller ones. Calculate pollution rates for different substances with this info.

- When Should We Use Estimates? When we don't have monitoring data, we use estimates. In a document called the Quantification Methodology Document (QMD), we have to explain how and why.

- Where do I put the info? The AEIR Form has spots for source monitoring info on worksheets 2.5 (for release points) and 3.6 (for non-point sources).

Keeping track of this data keeps the air clean and helps factories improve their operational cleanliness.

13.2 - Step 13b, Keeping an Eye on Pollution from Factories.

Here's what you need for this part:

This is like checking the factory's emissions. We use CEMS and stack sampling to see what's coming out. It helps us find out how much stuff in the air we're releasing.

The importance of source monitoring data can't be overstated. We can figure out how much pollution is coming from different parts of the factory. Calculating annual pollution rates for different substances requires the use of this data.

Estimates: Sometimes we don't have monitoring data, so we use estimates. In a document called the Quantification Methodology Document (QMD), we have to explain why we're doing that.

You can fill in this info on worksheet 2.5 of the AEIR Form. Enter this data:

- Monitoring (yes/no).

- Name of the monitored release point (like a smokestack).

- Please provide the CEMS Station ID and list the substances/parameters monitored if CEMS was used.

- Include the date(s) of stack sampling and the substances/parameters that were monitored if stack sampling was done.

This data helps us understand and control pollution from factories, making the air cleaner and safer.

13.3 - It's all about Keeping Track of Stuff in the Air

...from various sources at the industrial site in Step 13c:

Why We Monitor Non-Point Sources: We're not just watching big smokestacks -- we're also monitoring a variety of other sources called "non-point sources." These include things like storage tanks and vents where pollution might escape. All levels of management need to know what's going on.

Pollution control and environmental compliance

Pollution control and environmental complianceWe need to know what monitoring happened at these non-point sources during the year. Keeping track of what's going on helps us cross-reference when needed. Checking for leaks or emissions that might escape quietly is called fugitive monitoring. The substances or parameters that were monitored (like ammonia leaks) are noted on the form.

How Often We Check: We want to know how often facility employees check. Do they check these sources daily, weekly, quarterly, or at other intervals? It helps them figure out if there are persistent problems. It's also important to know how long they monitored. How long did they monitor each time?

We need to know when they checked, so they give us the dates.

Sometimes they divide the area into zones and take samples from each. Each zone has a number of samples, and we note how many they took.

Measured or Assigned: We need to know if the emissions were measured or if they were assigned based on a library. It helps us figure out if they took actual measurements or used estimates.

All this monitoring helps us make sure factories don't release harmful stuff in the air. Keeping our environment clean and safe is what it's all about.

Here is a more detailed look at Section 13.3:

Clause RC 7-N outlines the types of information that needs to be reported via the AEIR. There are mandatory and optional source monitoring fields on the AEIR Form. If you monitor non-point sources during the year, you have to fill out the AEIR Form. This is just identification and description info to cross-reference with the monitoring information and summaries already provided to the regulator.

Industrial operations just need to identify if any non-point sources were monitored, the monitored parameters, monitoring frequency and duration, and the test date(s). Below are examples of what type of source monitoring information is required in worksheet 3.6 of the AEIR Form.

Compliance with environmental laws

Compliance with environmental lawsIt's not necessary to include individual source monitoring results or summaries of monitoring information on this worksheet, since Alberta Monitoring Directive (AMD) Reporting Chapter or applicable Environmental Protection and Enhancement Act (EPEA) approval conditions have already required the monitoring results to be submitted.

Table 52 in Appendix C of the AEIR Standard shows the data fields for worksheet 3.6: Non-Point Source - Source Monitoring.

Did the industrial operation monitor any non-point sources using fugitive monitoring or other non-point source monitoring? (y/n)? You can check this box if any non-point sources at the industrial operation were monitored using fugitive monitoring or other non-point source monitoring during the inventory year by selecting "Yes" or "No".

AEIR Form worksheet 3.6 does not need to be filled out if there were no fugitive or other sources monitored non-point sources. Otherwise, non-point source information shouldn't be left blank. Include:

- Descriptive name for non-point sources

- Vents for ammonia tanks (for example)

The Non-Point Source Descriptive Name is carried over from worksheet 3.0. You don't have to fill it out. However, did you use fugitive monitoring or any other non-point source monitoring? (y/n)? This field lets you pick "Yes" or "No" to indicate whether the specific non-point source was monitored using fugitive monitoring or other non-point source monitoring during the inventory year.

Non-point sources that weren't fugitives or otherwise monitored during the inventory year don't need to have the remaining monitoring information fields filled out. Again, non-point source monitoring information shouldn't be left blank.

How many Sampling methods were used? This field asks how many sampling methods were used on the non-point source releasing stuff in the air. In the next field (Non-Point) you'll see the number of sampling methods.

In worksheet 3.6 of the AEIR Form, there are Source Monitoring Descriptions 1-15). This field must be filled in if you're reporting non-point source monitoring info.

- Description 1 of non-point source monitoring

- Monitoring 1: What we did

- Detecting fugitive leaks

This field asks for a brief description of the non-point source monitoring. You can't leave this field blank if you're reporting non-point source monitoring info.

What substances/parameters were monitored? (list them all)

e.g., Ammonia - List all the substances/parameters that were monitored for the non-point source here. You can't leave this field blank either if you're reporting non-point source monitoring.

Please be aware that grouping some substances/parameters together may be acceptable if there are more than can be entered individually. There's no need to report emissions of substances monitored beyond Schedule 1 and Schedule 2 on the AEIR form.

Did emissions get measured or assigned based on a library? e.g., measured - In this field, you have to say whether the emissions were measured or if they were assigned from a library. This field must be filled in if you're reporting non-point source monitoring info.

Frequency of monitoring e.g., quarterly - Identify the monitoring frequency for the non-point source in this field. This field must be filled out if you're reporting non-point source monitoring information.

Duration of monitoring - e.g., 3-hour intervals - Identify the typical monitoring duration for each sampling period for non-point sources. You can't leave this field blank if you're reporting non-point source monitoring.

Period(s) of sampling e.g., March, June, September, December

In this field, you'll need to list all the sampling periods for the non-point source. This field must be filled in if you're reporting non-point source monitoring.

List of applicable sampling dates for the inventory year - In this field, you'll need to list the dates that the non-point source was sampled during the inventory year.

Emission zones for the inventory year if applicable - The number of emission zones for the non-point source sampling needs to be entered here.

List the typical number of samples taken per emission zone - Listed here is the typical number of samples taken per emission zone, if applicable. For each zone, a different number of samples should be taken (e.g., 3 for zone A, 5 for zone B, etc.).

On worksheet 3.6 of the AEIR Form, you'll find additional source monitoring information fields for up to fifteen different types of non-point source monitoring methods. In the AEIR Standard, these fields aren't repeated.

Calvin Consulting Group Ltd. can help with air emissions reporting.

Is your industrial facility subject to the Environmental Protection and Enhancement Act (EPEA) approval? If so, you know how important it is to keep an accurate inventory of your emissions and contaminants. There can be serious consequences if you don't comply.

Calvin Consulting Group Ltd. specializes in helping industrial facilities like yours submit Annual Emissions Inventory Reports (AEIRs). We make sure you meet all AEIR deadlines and thresholds, protecting your operations as well as the environment.

Our consulting services align with source monitoring steps:

Source Monitoring: We help you make sure emissions data are accurate.

Facility Emissions Control: We'll help you understand and control pollution associated with your facility. Determining pollution rates for different substances becomes seamless and precise with our help.

Wide variety of sources: From big smokestacks to storage tanks, our comprehensive reporting covers key details such as monitoring frequency, duration, and sampling dates.

Get our help making sure your facility stays compliant by sending a question or two to

You're investing in the health of our environment and community when you partner with Calvin Consulting Group Ltd. We'll handle your AEIR submissions, so you can focus on what you do best.

Clean air is our Passion...Regulatory Compliance is our Business.

Learn about source monitoring, continuous emission monitoring, stack sampling, and leak detection.

All to better understand industrial emissions' impact on air quality. Discover why source monitoring data is so valuable these days, how we use the estimates we make, and how to fill out the AEIR Form and stay compliant with regulations.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.